What is Optical Lenses?

Mirrors are most likely the most commonly used optical elements in your laboratory, as well as their quality, efficiency, and also integrity are crucial to the success of your experiment. That's why we provide a variety of mirrors so you can be assured to discover what you require. When selecting an Optical Mirror, bear in mind the reflectivity, laser damage resistance, and coating resilience. For fast delivery, all our mirrors are delivered from the supply.

1. Mirrors for optics.

Optical lenses have a smooth, highly-polished, aircraft, or curved surface for showing light. Typically, the mirroring surface area is a thin finish of silver or lightweight aluminum on the glass. Product specifications for optical mirrors consist of size, the radius of curvature, density focal length, and surface high quality. The diameter or elevation of an optical mirror is measured directly on. If the optical mirrors curvature was extrapolated right into a ball, after that the span of that sphere is the radius of curvature for the mirror.

There are 2 thickness dimensions for optical mirrors: facility thickness and edge thickness. Devices of the procedure consist of inches, feet, and lawns; nanometers, centimeters, and also millimeters, as well as miles and also kilometers. With optical mirrors, focal size is the distance from the mirror at which light converges.Surface high quality describes digs as well as scrapes. A dig is a problem on a sleek optical surface area that is nearly equal in terms of length and size. A scrape is a problem whose length is many times its width.

2. Material

Optical lenses are made from several materials, each of which influences the mirrors reflectivity attributes. Choices for materials include borosilicate glass, copper, fused silica, nickel, and optic crown glass.

Borosilicate glass is likewise called BK7 as well as boro-crown glass. Copper is used in high-power applications as a result of its high thermal conductivity. Fused silica has a really low coefficient of thermal development and appropriates for use with moderately-powered lasers or changing environmental problems. Ultraviolet (UV) grade optical mirrors are additionally frequently readily available. Nickel is used in applications that require resistance to both thermal as well as physical damage.

3. Coatings

Optical mirrors are sometimes coated to enhance their reflectivity. Options consist of bare, enhanced, and secured lightweight aluminum; silver, bare gold, and also protected gold; and coatings made from rhodium as well as dielectric materials. Enhanced lightweight aluminum coatings are utilized to enhance reflectance in the visible and also ultraviolet areas.

Protected lightweight aluminum coatings give abrasion resistance while securing the surface area of the aluminum, an outstanding reflector in the upper UV, noticeable, and near-infrared (IR) regions. Optical mirrors with bare gold and also shielded gold coatings are used in the near-IR to far-IR regions. Silver finishings give much better reflectance than aluminum; nonetheless, silvers propensity to oxidize and also stain needs extensive securing from the environment. Rhodium finishes have a reflectivity of approximately 80% of the visible spectrum.

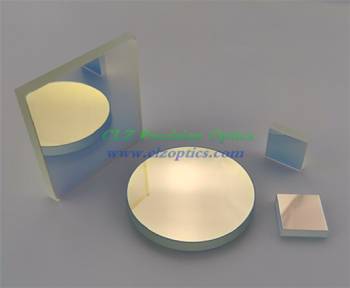

There are our products:

Dielectric Mirrors

A. Dielectric Coatings

Dielectric mirrors offer greater reflectivity over a wide spooky range of a few 100 nm. Their finish is a lot more long-lasting, making them much easier to cleanse, as well as more resistant to laser damages.

B. UV Coatings.

Mirrors with a UV Aluminium finish to enable the detection of UV wavelengths from 180nm and also the form can make a rectangle as well as a square.

4. Selecting an Optical Mirror

We can produce custom optical mirrors that are a variety of reflective coverings from personalized optical finishes readily available upon request. And also we can give custom made openings on an optical mirror to meet your demands, we can do machined opening without cracks on the internal side of the hole.

评论

发表评论