What are the Advantages of using Meniscus Lenses in Infrared Applications?

As a Spherical Lenses Manufacturer, share with you.

Benefits of meniscus design

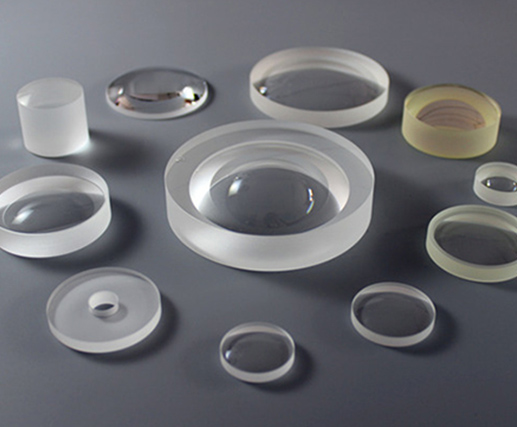

Compared to many other shapes of optical lenses, Meniscus Lenses rarely provide finished products. Meniscus Lenses are mainly used for focusing small spots or collimating applications, while plano-convex lenses are often superior in price / performance.

Meniscus Lenses

Spherical aberration

Due to the spherical nature of the lens, spherical aberrations produce parallel rays from the optical axis at different distances, without intersecting at the same point. Although multiple lenses can be used to correct spherical aberrations, it is best to minimize the number of lenses for many infrared systems where the material cost is much higher than the visible material. There is no need to use multiple lenses. By shaping the lenses into the best shape, the spherical aberration of a single lens can be minimized.

For a fixed index of refraction and lens thickness, there are an unlimited number of combinations of radii that can be used to create lenses of a specific focal length. These combinations of radii produce different lens shapes, and the curvature of light as it passes through the lens directly causes spherical aberration and coma.

The lens shape can be described by the Coddington form factor C.

By using the thin lens aberration equation, we can obtain the conditions that produce the smallest spherical aberration.

Assuming a constant wavelength can be maintained, the relationship between the index and form factor that produces the smallest spherical aberration can be visualized.

Benefits of meniscus design

When working in a visual environment, the glass index is generally between 1.5 and 1.7, and the shape of the smallest spherical aberration is almost plano-convex. However, in the infrared environment, higher index materials like germanium are often used. The index of germanium is 4.0. By greatly reducing the spherical aberration, the great benefit of meniscus lens design is obtained.

Minimal spherical aberration occurs when the light rays are evenly curved on both interfaces. Although the first surface of the germanium meniscus lens will cause the light to bend slightly more than similar PCX lenses, the second surface of the PCX lens will cause the light to be more curved, resulting in an overall increase in spherical aberration.

Comparing the performance of a 25 x 25 mm germanium PCX lens to a 25 x 25 mm germanium meniscus lens, it is easy to see how a PCX lens bends light more significantly relative to the lens surface than a meniscus lens. The increase in curvature results in an increase in spherical aberration. The germanium meniscus lens shows a sharp drop in spot size, making it more suitable for demanding infrared applications.

When using a meniscus shape, the spot size of the germanium lens is greatly reduced. Although a meniscus lens may not provide benefits in all applications, it can provide significant cost and performance advantages for many infrared applications, including spectroscopy and thermal imaging.

Our company also has UV Grade Fused Silica Lenses on sale, welcome to consult.

评论

发表评论