What is the production process of Fused Silica Mirrors?

Fused quartz or quartz glass is an amorphous form composed of quartz. It differs from traditional glass in that it has no other ingredients and is usually added to the glass to lower the melt temperature. Therefore, fused silica has a higher working and melting temperature. Purity is an important index of quartz glass, which has a great impact on physical and chemical properties and use performance, such as devitrification, high temperature strength, softening point, light transmission, thermal stability, chemical stability, radiation resistance, fluorescence characteristics, etc.; The purity of the material is controlled below the order of ppb, so quartz glass should be controlled at the order of PPm to meet the needs of the semiconductor industry. Fused silica has better optical and thermal properties than other types of glass, mainly due to its purity. To sum up these reasons, it has a wide range of applications, such as semiconductor manufacturing and laboratory equipment. Fused Silica Mirrors have better UV transmission than most other glasses, so they are used to make the UV spectrum of lenses and other optical systems. Its low coefficient of thermal expansion also makes it a useful mirror substrate for useful materials.

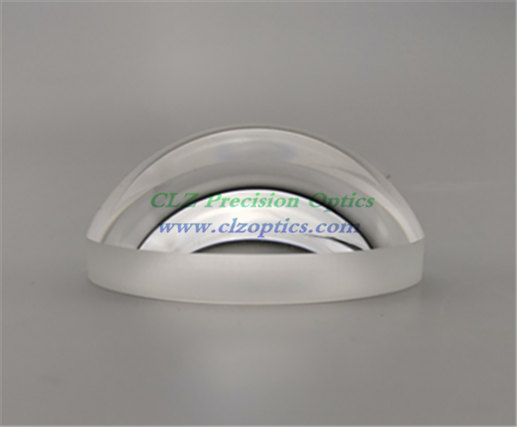

Fused Silica Mirrors

As a Fused Silica Precision Lenses Supplier, share with you the manufacturing process of fused silica glass:

1. Raw material

Fused silica is made from fused (fused) high-purity quartz sand, which is produced from quartz crystals. Quartz contains only silicon and oxygen, but commercial quartz glass often contains impurities. The main impurities are aluminum and titanium.

2. Fusion

Melting is performed at about 2000 ° C using an electric heating furnace (electric melting) or a gas/oxygen fuel furnace (flame melting). Fused silica can be almost all silicon-rich chemical precursors, usually using a continuous process, which involves the flame-oxidized silica of volatile silicon compounds, and the resulting dust from thermal melting (although there are alternative processes ). This will result in deep ultraviolet light in a transparent glass with ultra-high purity and improved light transmission. A common method is to add silicon tetrachloride to a hydrogen-oxygen flame, but the use of this precursor results in environmentally unfriendly by-products, including chlorine and hydrochloric acid. To eliminate these by-products, new processes have been developed using alternative raw materials, which has also resulted in a higher purity fused silica, further improving deep ultraviolet light transmission.

3. Product quality

Fused silica is usually transparent, it is the process of fusing effects in a translucent material. However, due to the presence of small air bubbles trapped within the material, the material may appear opaque. Flame-melted materials always have high water content. Hydroxyl materials are formed in the furnace due to the combination of hydrocarbons and oxygen. This is a direction that Boxing has devoted to research for many years. After more than ten years of scientific practice, our company also has Fused Silica Precision Lenses on sale. Welcome to consult.

评论

发表评论