Without knowing this, I can't process Optical Glass Domes!

Optical Dome Lens differs from other glasses in that it is an integral part of an optical system and must meet the requirements of optical imaging. Its cold processing technology uses chemical vapor phase heat treatment and a single piece of soda-lime-silica glass to change its original molecular structure without affecting the original color and light transmittance of the glass, so that it meets the ultra-hardness standard, and meets fire protection requirements under high-temperature flame impact Super-hardness fire-resistant glass, its manufacturing method and special equipment. It is made of the following weight ratio components: potassium salt vapor (72% to 83%), argon (7% to 10%), gaseous copper chloride (8% to 12%), nitrogen (2 % ~ 6%).

It includes the following processes: cutting with soda-lime-silica glass as a the substrate, cold processing with fine grinding edges → chemical vapor-phase heat treatment of cold-processed soda-lime-silica glass → treatment of fire-resistant protective film on the surface of soda-lime-silica glass → The soda-lime-silica the glass surface is subjected to a special physical tempering treatment. The cylinder body, the cylinder head fitted with the cylinder body, and the reaction kettle integrated with the cylinder head form a special thermal decomposition gasification equipment.

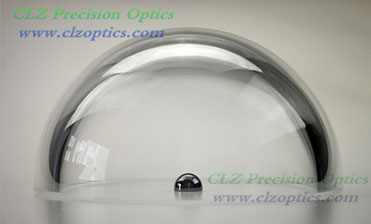

Optical Glass Domes

The following requirements are imposed on the quality of Optical Glass Domes:

1. Consistency of specific optical constants and optical constants of the same glass

Each type of optical glass has a prescribed standard refractive index value for different wavelengths of light, as a basis for optical designers to design optical systems. Therefore, the optical constants of the optical glass produced by the factory must be within a certain tolerance range of these values, otherwise, the actual imaging quality will not be consistent with the expected result at the time of design and affect the quality of the optical instrument. At the same time, because the same batch of instruments are often manufactured with the same batch of optical glass, in order to facilitate the unified calibration of the instrument, the allowable deviation of the refractive index of the same batch of glass is stricter than their deviation from the standard value.

2. Highly transparent

The brightness of the imaging of the optical system is proportional to the transparency of the glass. The transparency of the optical glass to a certain wavelength of light is represented by the light absorption coefficient Kλ. After the light passes through a series of prisms and lenses, part of its energy is lost to the interface reflection of the optical part and the other part is absorbed by the medium (glass) itself.

The former increases with the increase of the refractive index of the glass, and this value is very large for high refractive index glass, such as about 6% of the light reflection loss on the surface of the heavy glass. Therefore, for an optical system including multiple thin lenses, the main way to improve the transmittance is to reduce the reflection loss on the lens surface, such as coating the surface antireflection coating layer.

For large-size optical parts, such as the objective lens of an astronomical telescope, the transmittance of the optical system is mainly determined by the light absorption coefficient of the glass due to its large thickness. By improving the purity of glass raw materials and preventing any coloring impurities from being mixed in the whole process from batching to smelting, the light absorption coefficient of glass can generally be made less than 0.01.

We are Optical Glass Domes Factory, welcome to consult.

评论

发表评论